Expert in High-End CNC Machine Tools - ShengChuan

CNC Lathes & Turning-Milling Center Solutions

Corporate Vision

Driven by technological innovation, building a globally leading precision machine tool brand

Innovation-Driven, Creating the Future

Zhejiang Shengchuan Precision Machine Tool Co., Ltd. specializes in the R&D, manufacturing, and sales of high-end precision machine tools. Adhering to the corporate philosophy of "Excellence in Details, Innovation Leads the Future," we are committed to providing global customers with high-performance, high-precision industrial solutions.

The company has a modern production base of over 15,000 square meters, equipped with a team of senior technical talents from renowned machine tool enterprises in Japan, Taiwan, and mainland China, working together to build comprehensive technical capabilities and ensure product design and manufacturing reliability and stability.

CNC Machine Tools Product Center

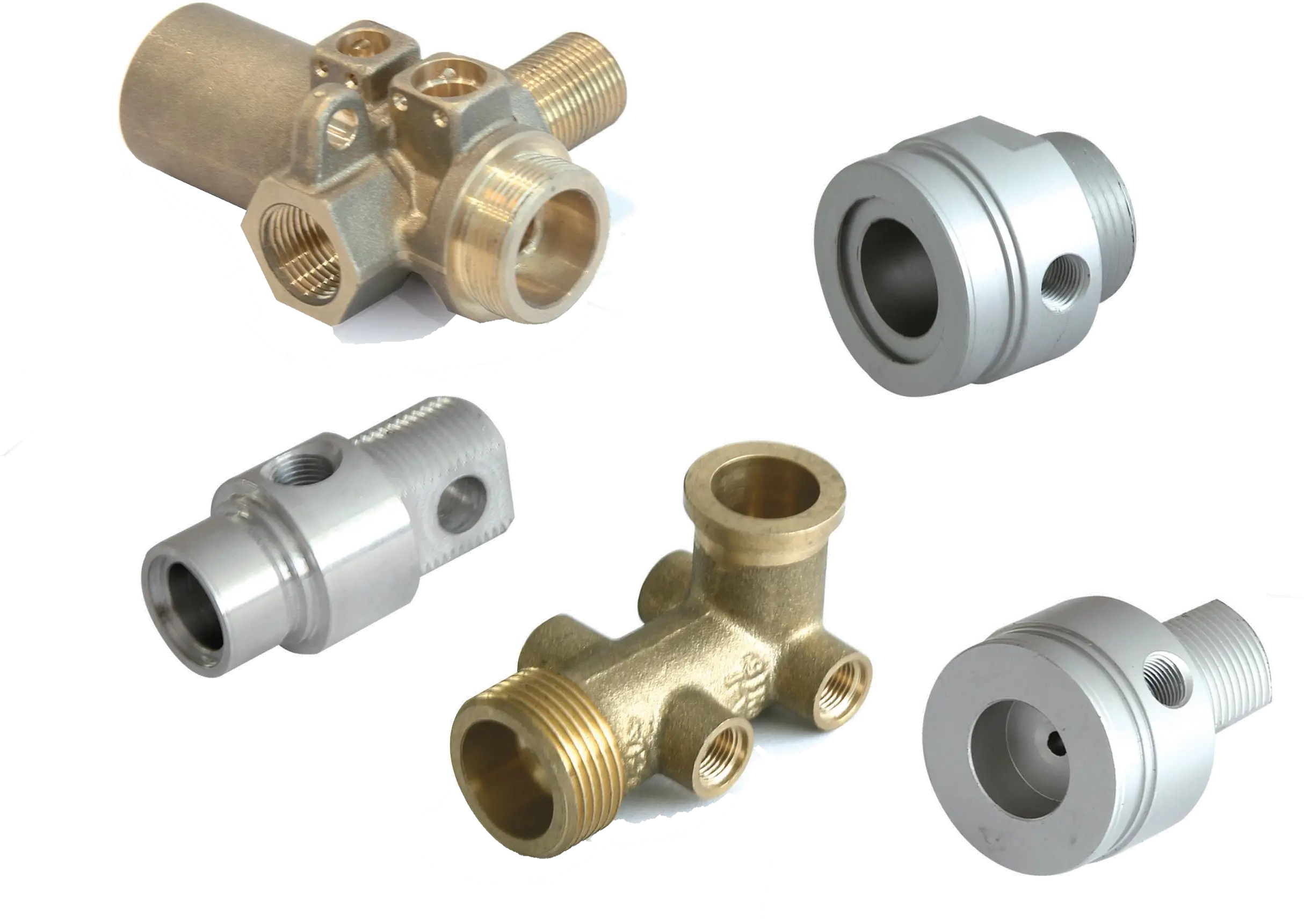

High-performance CNC machine tools to meet diverse industrial needs

CNC Lathes

High-end CNC lathes designed for small to medium-sized parts processing, featuring Japanese-style high-low rail 30° structure, equipped with high-torque spindles and 12-station turrets.

View CNC Lathes Details

Turning-Milling Centers

Turning-milling centers suitable for small to medium-sized parts processing, equipped with high-power spindles and automatic tool changing systems, delivering exceptional machining efficiency and precision.

View Turning-Milling Centers

Dual-Spindle Turning-Milling Centers

High-efficiency dual-spindle design significantly enhances production efficiency, especially suitable for mass production scenarios, enabling multi-surface machining in a single setup.

View Dual-Spindle CentersProfessional Service Guarantee

Comprehensive service system creating long-term value for CNC machine tool customers

Professional Pre-Sales Consultation

One-on-one service from professional engineers to provide optimal equipment selection based on your processing needs.

Installation & Commissioning

Professional team for on-site installation and commissioning, ensuring efficient equipment operation with operator training.

Rapid Response Maintenance

24-hour response time, 72-hour fault resolution.

Common spare parts shipped within 24 hours to ensure production continuity.