SC-5050(A2-6)

High-Low Rail CNC Lathe

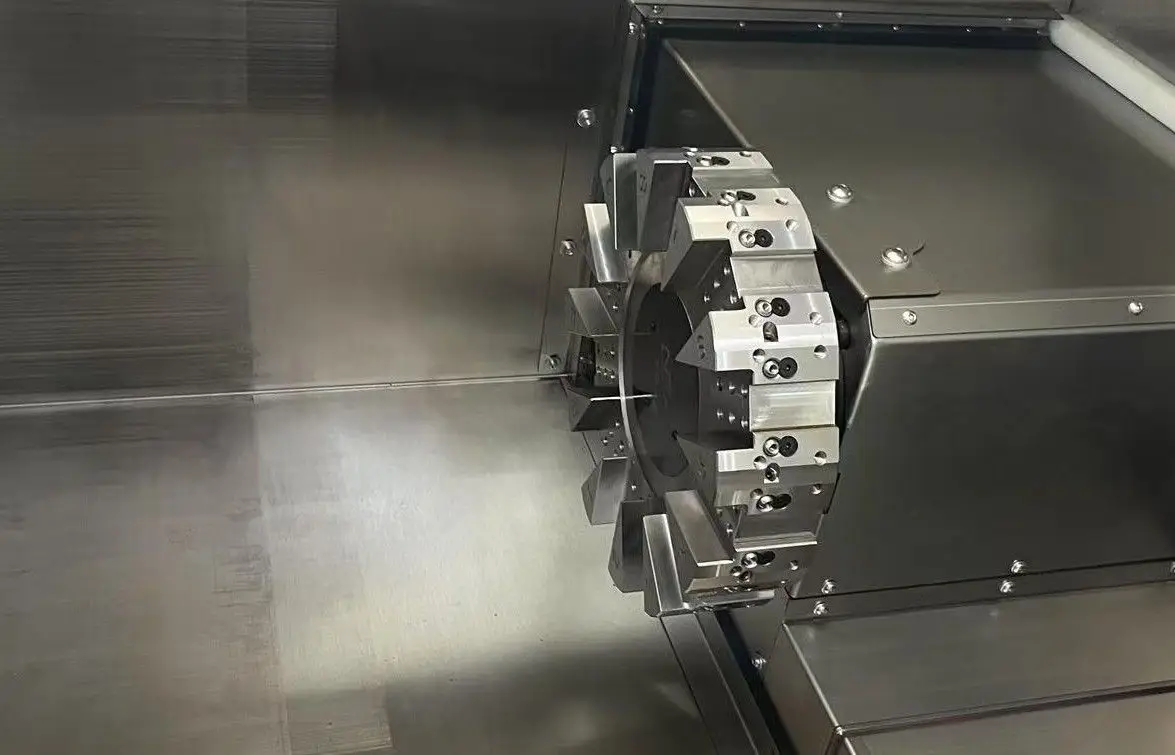

Turret Type

8/12-station Servo Turret

Main Motor

11kw

Hydraulic Chuck

8inch/200mm

A2-6 Mechanical Spindle

50-3000rpm

SC-5050(A2-6) series designed for small and medium-sized parts processing, featuring Japanese-style 30° high-low rail structure, high-torque mechanical spindle and 8/12-station servo turret for high rigidity cutting.

1. Heavy-duty structure: 45 roller 8-slider P-class heavy preload X/Z guides.

2. Powerful spindle: A2-6 mechanical spindle (2500r/min) + 62mm through hole for deep hole boring.

3. Large capacity: 520mm Z-axis travel + 8-inch hydraulic chuck supports 500mm long shaft parts.

4. Efficient tool change: 12-station servo hydraulic turret (turret Ø340mm), standard boring bar holder supports Ø32 boring bars.

5. Industrial-grade protection: Fully enclosed housing + built-in chip conveyor, optional chip conveyor.

6. Smart hydraulic station: 2.2kW pump unit + 65L tank ensures stable chuck/tailstock pressure.

High Precision High Rigidity Servo Hydraulic Turret

SC-5050(A2-6) uses high-performance 8/12-station servo hydraulic turret supporting continuous complex operations.

Servo motor indexing, precision gear positioning, hydraulic clamping structure.

Fully sealed turret interior, no lifting during indexing. Fast tool change, high positioning accuracy. Withstands 7Mpa high-pressure coolant.

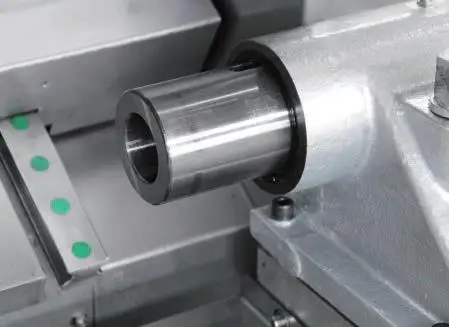

High Rigidity Spindle Unit

A2-6 mechanical spindle design with 11kw built-in direct drive motor.

High-torque design with precision bearing system maintains stable operation under low-speed heavy cutting conditions, excellent cutting capability.

Spindle through-hole diameter 63mm for easy machining of large shaft parts. Max spindle speed 3000rpm balances heavy cutting and precision machining.

High Rigidity Hydraulic Tailstock

Equipped with high-rigidity hydraulic tailstock system, manual adjustment range 320mm, automatic quill travel 100mm, MT5 taper design.

Eliminates shaft workpiece vibration for stable machining under heavy cutting conditions.

Ultra-rigid box-type bed structure resistant to thermal displacement.

SC-5050(A2-6) Technical Specifications

Detailed technical parameters

| Item | Specification | SC-5050(A2-6) |

|---|---|---|

| Capacity | Turret Spec | T8/T12 |

| Max Swing Diameter mm | 500 | |

| Standard Machining Diameter mm | 280 | |

| Max Machining Diameter mm | 420 | |

| Max Machining Length mm | 500 | |

| Bar Machining Diameter mm | 51 | |

| Travel | X-axis Travel mm | 240 |

| Z-axis Travel mm | 520 | |

| Spindle | Speed (min⁻¹) | 3000 |

| Min Index Angle (Cs-axis) deg | - | |

| Spindle Nose | A2-6 | |

| Bore Diameter mm | 62 | |

| Bearing Bore Diameter mm | 110 | |

| Turret | Turret Type | Direct Mount |

| Tool Stations (pcs) | 8/12 | |

| Rectangular Tool Shank Height mm | 25 | |

| Boring Bar Shank Diameter mm | 40 | |

| Tailstock | Tailstock Travel mm | 320 |

| Tailstock Quill Diameter mm | 75 | |

| Tailstock Quill Taper | MT.5 | |

| Tailstock Quill Travel mm | 100 | |

| Feed Rate | Rapid Traverse m/min | X:24 / Z:30 |

| Motor | Spindle Motor (30min 60%/cont) kW | 11/15 |

| Live Tool Motor (15min/cont) kW | - | |

| Feed Axis Motor kW | X:1.5 / Z:1.5 | |

| Hydraulic Pump Motor kW | 1.5 | |

| Coolant Pump Motor kW | 0.4 | |

| Power Supply | Power Capacity kVA | 15 |

| Tank Capacity | Hydraulic System L | 65 |

| Lubrication Oil L | 3 | |

| Coolant L | 120 | |

| Dimensions/Weight | Machine Height mm | 1700 |

| Floor to Spindle Center mm | 1020 | |

| Footprint (Standard) mm×mm | 2400×1650 | |

| Machine Weight kg | 3500 |

Get SC-5050(A2-6) Technical Details

Contact us now for customized solutions and quotes