STFH-780

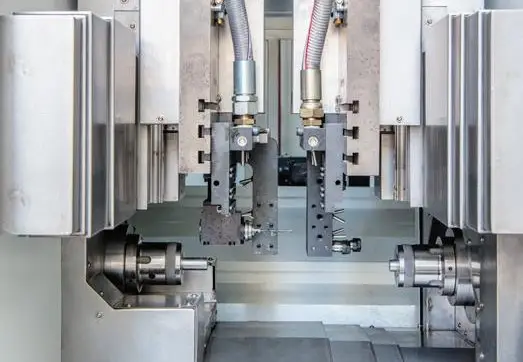

Dual-Spindle Dual-Gantry Turning-Milling Compound Machine

Double Turret, Double Power Head, Double Y-axis

5-station turret + 3-station power head + 6-station boring tool holder ×2

Dual Main Motors

Taiwan Yucheng 18.5kw ×2

Cast Iron Bed

HT300

Dual A2-5 Permanent Magnet Synchronous Electric Spindle

50-5000rpm

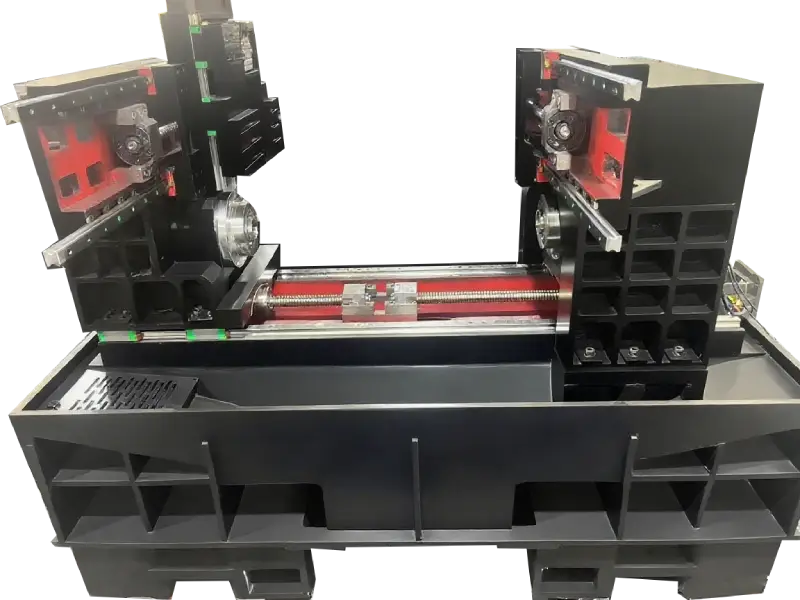

The STFH-780 series is designed for efficient processing of complex parts, adopting a dual-spindle butt processing method. The Dual-Gantry structure provides stable horizontal movement and lightweight vertical movement. Both sides are equipped with multiple tool turrets, three-axis power heads, and multi-hole boring-drilling tool holders, capable of simultaneously performing turning, milling, boring, drilling and other processing on complex parts, achieving one-time processing completion without secondary clamping and multi-process machining.

Dual Spindle Synchronous Processing System

The STFH-780 uses two high-precision electric spindles from Taiwan Yucheng YCD200 type, with a maximum spindle bore diameter of 46mm, speed range of 50-5000 rpm, rated speed of 3000 rpm. The dual spindle design significantly improves processing efficiency, especially suitable for mass production.

The left main machine is designed with a 6-station tool turret, 3-station power head, and 6-station boring-drilling tool holder; the right side is designed with a 4-station tool turret (can be customized to 6 stations as needed), 3-station power head, and 6-station boring-drilling tool holder.

Adopting dual-spindle butt processing method, the Dual-Gantry has advantages of stable horizontal movement and lightweight vertical movement.

High Precision Rigid Structure

Using HT300 high-strength cast iron bed to ensure long-term stable operation. Imported C3-grade screw linear rails provide high rigidity and high precision motion control, Japan NSK-P4 grade angular contact bearings ensure long-term stable spindle operation.

The Dual-Gantry structure design provides excellent horizontal movement stability and lightweight vertical movement, especially suitable for high-precision processing of complex parts.

The overall structure has been optimized through finite element analysis to ensure stability during high-speed machining. The base adopts a wide design to increase equipment stability and reduce vibration impact on machining accuracy.

Multi-process Compound Machining Capability

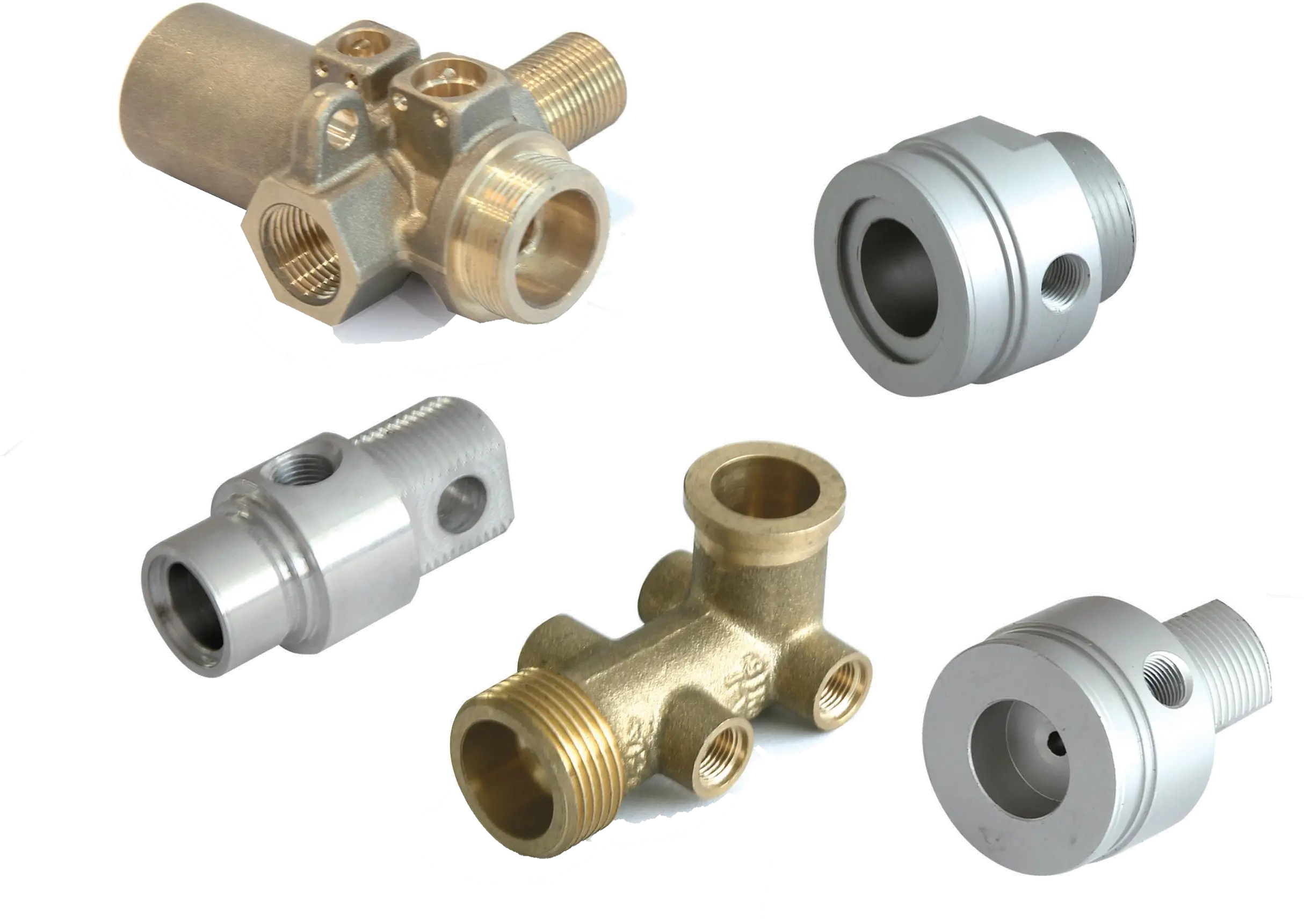

Both sides can simultaneously perform turning, milling, boring, drilling and other processing on various complex parts, achieving one-time completion of complex parts processing without secondary clamping and multi-process machining. Significantly improves part machining accuracy and efficiency.

Equipped with a Shindengren dual-channel controllable 10-axis high-end CNC system, capable of simultaneously controlling multi-axis linkage to achieve high-precision machining of complex surfaces.

The tool magazine design is reasonable with short tool change time, improving overall equipment utilization.

Especially suitable for pneumatic industry, explosion-proof industry, sealing industry and various complex parts processing requirements.

STFH-780 Technical Specifications

Detailed technical parameters

| Item | Specification | STFH-780 |

|---|---|---|

| Axis | Number of Spindles | 2 |

| Spindle Taper Type | A2-5 | |

| Spindle Through Hole Diameter (mm) | 46 | |

| Travel 1 - X-axis (mm) | 640 | |

| Travel 1 - Y-axis (mm) | 155 | |

| Travel 1 - Z-axis (mm) | 258 | |

| Travel 2 - X-axis (mm) | 640 | |

| Travel 2 - Y-axis (mm) | 155 | |

| Travel 2 - Z-axis (mm) | 719 | |

| Speed | Spindle Speed (r/min) | 50 - 5000 |

| Rapid Feed (mm/min) | 24000 | |

| Cutting Feed (mm/min) | 10000 | |

| Tool Magazine | Turret (sets) | 2 |

| Left Turret Stations | 6 | |

| Right Turret Stations | 4 | |

| Left Power Milling Heads | 3 | |

| Right Power Milling Heads | 3 | |

| Turret Tool Holder Size (mm) | 12x12 | |

| Boring Tool Shank Diameter (mm) | 20 | |

| Torque | Electric Spindle (Max Torque) (N.M) | 80 |

| Motor (Max Torque) - X-axis (N.M) | 11 | |

| Motor (Max Torque) - Y-axis (N.M) | 11 | |

| Motor (Max Torque) - Z-axis (N.M) | 18.6 | |

| Power Head Motor (Max Torque) (N.M) | 8.3 | |

| Power | Electric Spindle (Power) (KW) | 19 |

| X-axis Motor (Power) (KW) | 2.4 | |

| Y-axis Motor (Power) (KW) | 2.4 | |

| Z-axis Motor (Power) (KW) | 3.9 | |

| Power Head Motor (Power) (KW) | 1.7 | |

| Machine Size/Weight | Dimensions (L×W×H) (mm) | 3000×2200×2300 |

| Total Weight (kg) | 7000 |

Get Detailed Technical Specifications for STFH-780

Contact us immediately for exclusive solutions and preferential quotations