SC-5050D

High-Low Rail Turn-Mill CNC Machine

Power Turret

12 Station BMT-55

Main Motor

15kw

Hydraulic Chuck

8 inch/200mm

A2-6 Electric Spindle

50-3000rpm

The SC-5050D series is designed for large part machining. Features Japanese-style 30° high-low rail structure, high-torque electric spindle and 12-station BMT-55 turret, providing excellent heavy cutting capability and machining accuracy.

1. Large workpiece machining: 550mm swing diameter, Ø66mm through hole, max machining length 450mm.

2. Ultra-strong rigid structure: X/Z axis 45 roller rails (heavy preload P-grade) + 4008/4012 ball screws (C3-grade).

3. Direct-drive spindle system: 15kW built-in motor (50-3000r/min), low center of gravity design enhances heavy cutting stability.

4. High-efficiency power tools: 3.1kW power head (5000r/min), supports various tool holders and power head expansions with BMT55 interface.

5. Hydraulic enhancement: 2.2kW/60L hydraulic system, compatible with 8-inch hollow chuck.

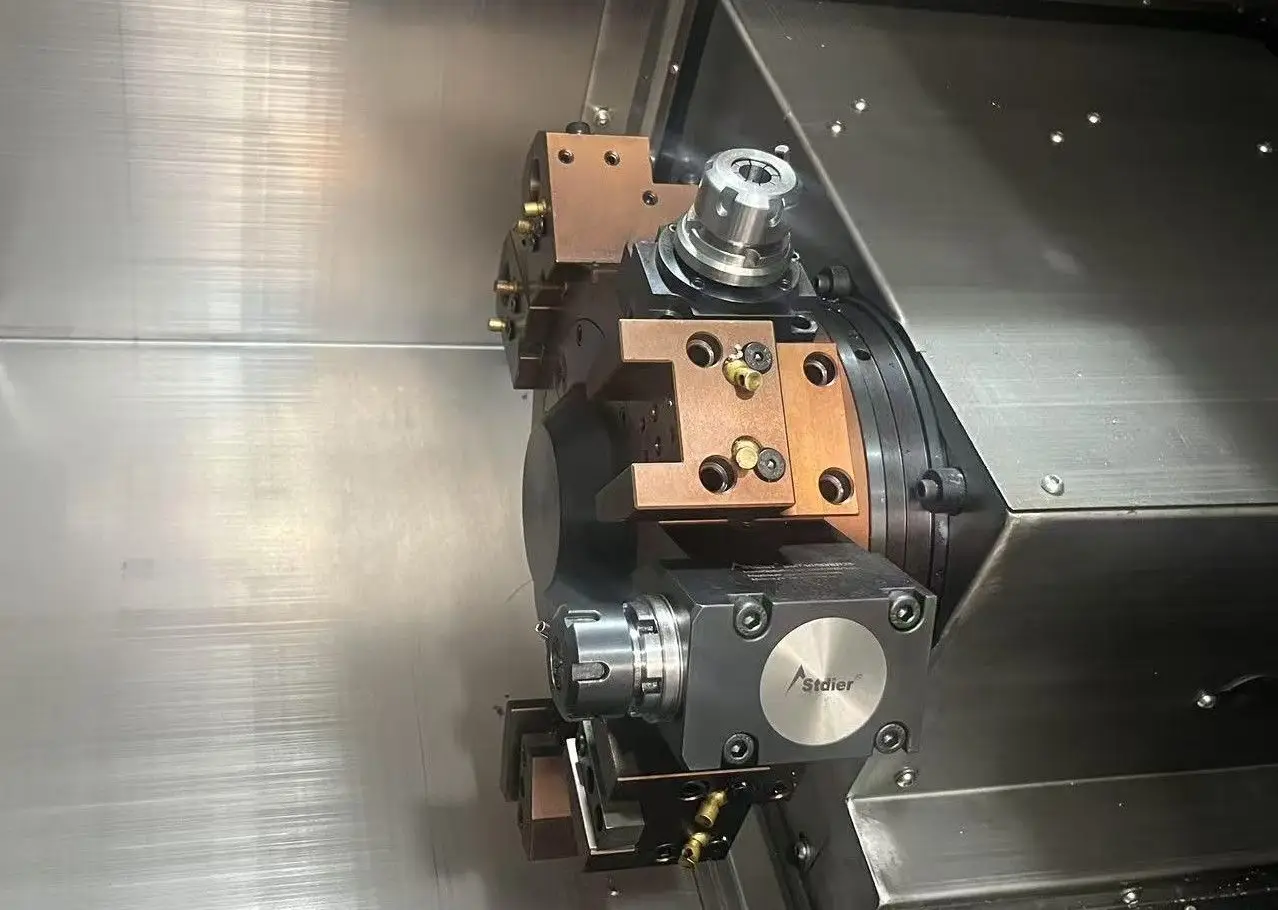

High-Precision High-Rigidity Power Turret

SC-5050D adopts high-performance 12-station BMT-55 turret. Tools can be directly installed without additional adapter plates, greatly reducing tool change time and tool vibration.

Bidirectional positioning, short tool change time, high positioning accuracy. Optional power tool holders enable turning, milling, boring, drilling, tapping and other operations. Capable of complex turn-mill composite machining.

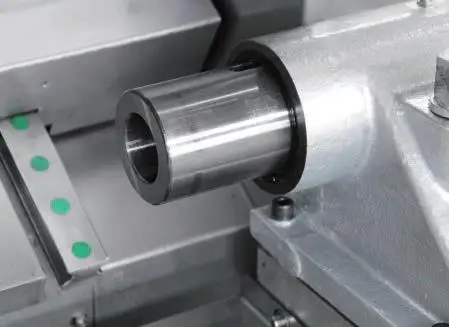

Electric Spindle

Adopts A2-6 electric spindle design with 15kw built-in direct-drive motor.

"Zero transmission" eliminates vibration from belts, thermal expansion errors during milling, and indexing errors from buffering. Saves 30% power compared to traditional mechanical spindles under same conditions.

Spindle through-hole diameter up to 66mm, easily processes large shaft parts. Maximum spindle speed 3000rpm, meeting both heavy cutting and precision machining requirements.

High-Rigidity Hydraulic Tailstock

Equipped with high-rigidity hydraulic tailstock system. Manual adjustment stroke 300mm, automatic sleeve stroke 100mm, Morse Taper No. 5 design.

No need to worry about shaft workpiece vibration issues, achieving stable machining under powerful cutting conditions.

Super high-rigidity box-type bed structure resistant to thermal displacement.

SC-5050D Technical Specifications

Detailed technical parameters

| Item | Specification | SC-5050D |

|---|---|---|

| Machining Capacity | Turret Specification | T12 |

| Max. Swing Diameter (mm) | 550 | |

| Standard Machining Diameter (mm) | 280 | |

| Max. Machining Diameter (mm) | 400 | |

| Max. Machining Length (mm) | 450 | |

| Bar Machining Diameter (mm) | 51 | |

| Travel | X-axis Travel (mm) | 240 |

| Z-axis Travel (mm) | 410 | |

| Spindle | Speed (min⁻¹) | 50-3000 |

| Min. Indexing Angle (Cs axis control) (deg) | - | |

| Spindle Nose (Nominal Size) | A2-6 | |

| Through Hole Diameter (mm) | 66 | |

| Bearing Bore (mm) | 110 | |

| Turret | Turret Type | Direct Mounting |

| Number of Tools | 12 | |

| Rectangular Tool Shank Height (mm) | 25 | |

| Boring Bar Shank Diameter (mm) | 32 | |

| Tailstock | Tailstock Travel (mm) | 300 |

| Tailstock Sleeve Diameter (mm) | 75 | |

| Tailstock Sleeve Taper | MT.5 | |

| Tailstock Sleeve Travel (mm) | 100 | |

| Feed Rate | Rapid Traverse (m/min) | X:25 / Z:25 |

| Motor | Spindle Motor (30min 60%/cont.) (kW) | 15 |

| Rotary Tool Motor (15min/cont.) (kW) | 3.2 | |

| Feed Axis Motor (kW) | X:2.4 / Z:2.4 | |

| Hydraulic Pump Motor (kW) | 1.5 | |

| Coolant Pump Motor (kW) | 0.55 | |

| Power Supply | Power Capacity (kVA) | 15 |

| Tank Capacity | Hydraulic Oil (L) | 65 |

| Lubricating Oil (L) | 3 | |

| Coolant (L) | 120 | |

| Dimensions/Weight | Machine Height (mm) | 1650 |

| Height to Spindle Center (mm) | 1020 | |

| Footprint (Standard) (mm×mm) | 2400×1650 | |

| Machine Weight (kg) | 3800 |

Get Detailed Technical Specifications for SC-5050D

Contact us now for customized solutions and special offers