SC-4036E

High-Speed High-Low Rail Lathe

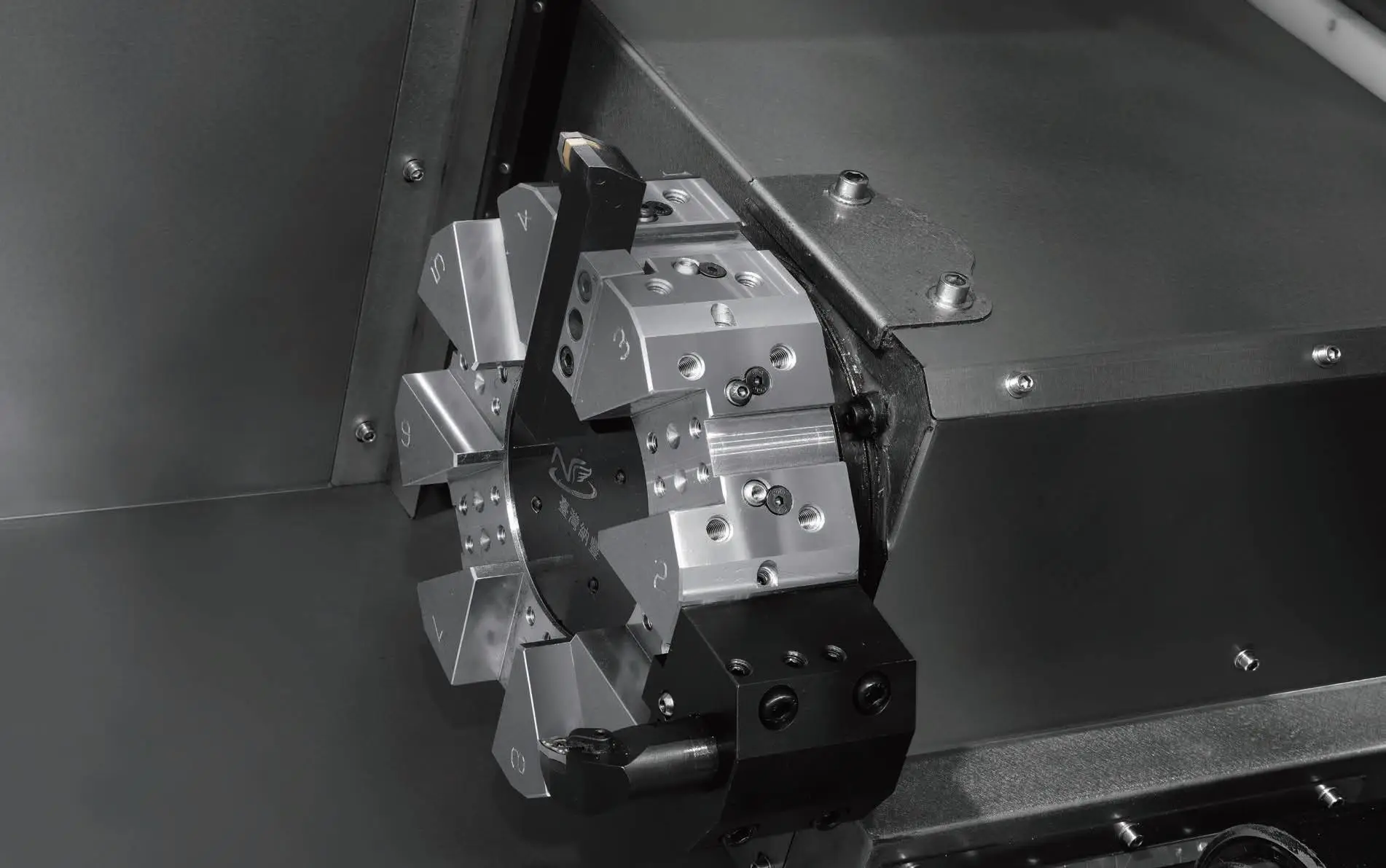

Turret Type

8-station Servo Turret

Main Motor

7.5kw

Hydraulic Chuck

6-inch/160mm

A2-5 Electric Spindle

50-3000rpm

SC-4036E series is designed for small-medium parts processing. Adopts Japanese high-low rail 30° structure, equipped with high-torque spindle and 8-station servo turret. Full linear rail heavy preload structure ensures high-speed cutting stability. Standard high-pressure coolant achieves mirror turning effect.

1. High-speed electric spindle: A2-5 direct drive spindle (50-3000rpm), 36mm through hole, suitable for precision small hole machining.

2. Anti-vibration structure: Japanese high-low rail + heavy preload roller guides, maintains ±0.01mm precision even at high speeds.

3. Dynamic response optimization: X/Z-axis 8N servo motors with brakes, 15-25m/min rapid traverse.

4. Compact automation: 8-station servo turret + 6-inch hollow hydraulic chuck, supports thin-wall part anti-deformation machining.

5. Clean production: 370W high-pressure pump + full sealed protection, optional side chip removal saves space.

6. Energy-saving design: Low resistance linear guides + intelligent lubrication system reduces energy consumption by 30%.

Powerful Turret System

SC-4036E uses 8-station servo turret, supporting continuous complex operations.

Servo motor indexing, precision gear positioning, hydraulic clamping structure.

Fully sealed turret, no lifting during rotation. Fast tool change, high positioning accuracy. Withstands 7Mpa high-pressure hydraulic.

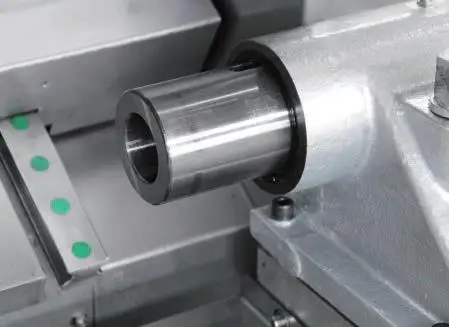

High-Rigidity Spindle Stage

Adopts A2-5 electric spindle design with 7.5kw built-in motor.

High-torque design combined with precision bearing system maintains stable operation even under low-speed heavy load cutting conditions, with excellent cutting capability.

Spindle through-hole diameter up to 46mm, easily processes small-medium shaft parts. Max spindle speed 3000rpm.

High-Rigidity Hydraulic Tailstock

Equipped with high-rigidity hydraulic tailstock system. Manual adjustment stroke 140mm, automatic sleeve stroke 100mm, Morse taper #5 design.

No worry about shaft workpiece wobble, ensures stable machining under heavy cutting conditions.

Ultra-rigid box-type bed structure resistant to thermal displacement.

SC-4036E Technical Specifications

Detailed technical parameters

| Item | Specification | SC-4036E |

|---|---|---|

| Machining Capacity | Turret Specification | T8 |

| Max Swinging Diameter mm | 450 | |

| Standard Machining Diameter mm | 160 | |

| Max Machining Diameter mm | 280 | |

| Max Machining Length mm | 360 | |

| Bar Machining Diameter mm | 35 | |

| Travel | X-axis Travel mm | 130 |

| Z-axis Travel mm | 300 | |

| Spindle | Speed (min⁻¹) | 3000 |

| Min Indexing Angle (Cs control) deg | - | |

| Spindle Nose | A2-5 | |

| Spindle Through Hole Diameter mm | 46 | |

| Bearing Bore Diameter mm | 90 | |

| Turret | Turret Type | Direct Mount |

| Tool Capacity (pcs) | 8 | |

| Rectangular Tool Shank Height mm | 25 | |

| Boring Bar Shank Diameter mm | 40 | |

| Tailstock | Tailstock Travel mm | 140 |

| Tailstock Sleeve Diameter mm | 75 | |

| Tailstock Sleeve Taper | MT.5 | |

| Tailstock Sleeve Travel mm | 100 | |

| Feed Rate | Rapid Traverse m/min | X:30 / Z:30 |

| Motors | Spindle Motor (30min 60%/cont) kW | 7.5 |

| Rotary Tool Motor (15min/cont) kW | - | |

| Feed Axis Motor kW | X:1.5 / Z:1.5 | |

| Hydraulic Pump Motor kW | 1.5 | |

| Coolant Pump Motor kW | 0.4 | |

| Power Requirement | Power kVA | 11 |

| Tank Capacity | Hydraulic System L | 50 |

| Lubrication Oil L | 2 | |

| Coolant L | 60 | |

| Machine Dimensions/Weight | Machine Height mm | 1650 |

| Floor to Spindle Center Height mm | 980 | |

| Footprint (Standard) mm×mm | 2000×1400 | |

| Machine Weight kg | 2400 |

Request SC-4036E Technical Details

Contact us for custom solutions and special offers