SC-4036DY

High-Low Rail Turning-Milling CNC Machine

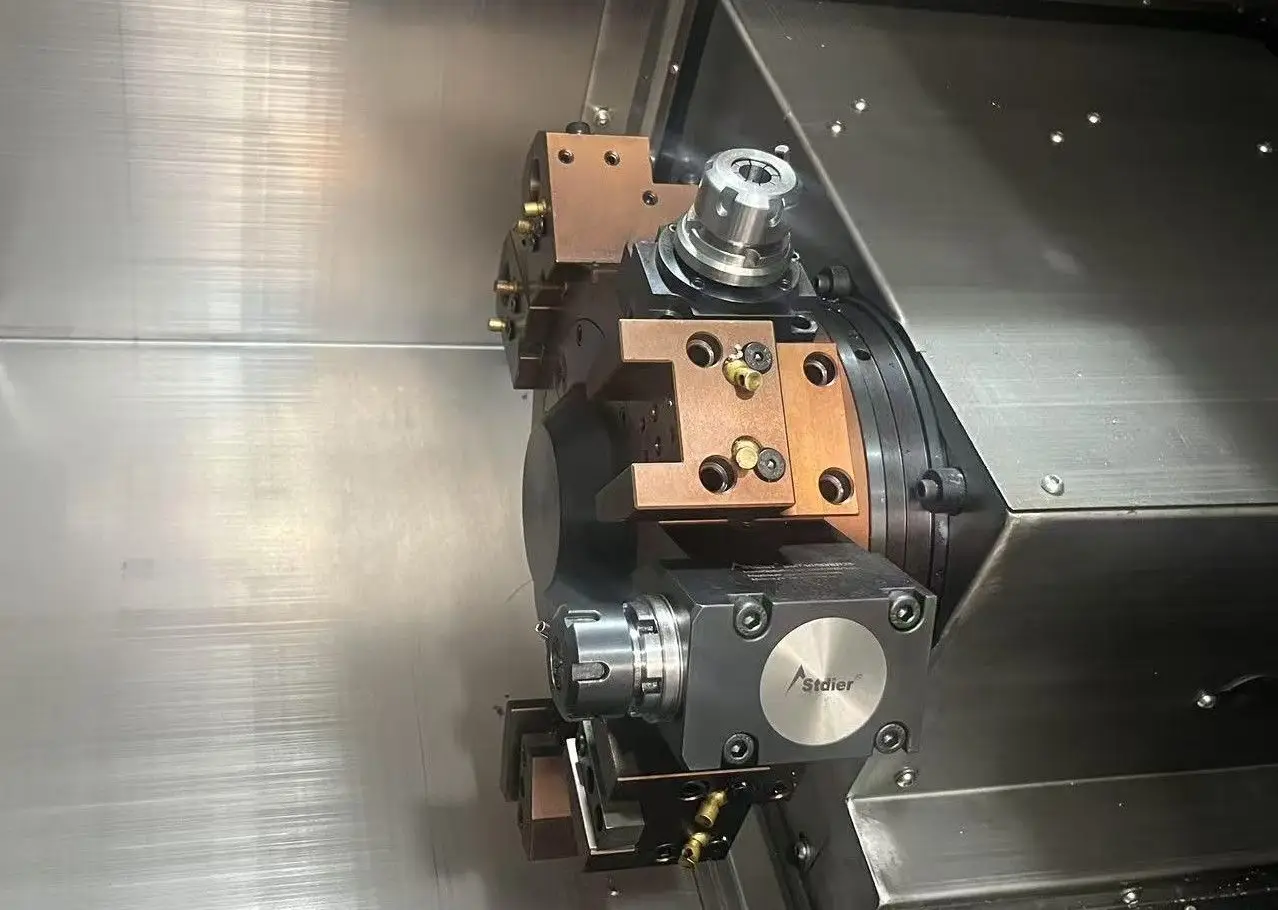

Power Turret

12-station BMT40

Main Motor

7.5kw Built-in Direct Drive

Hydraulic Chuck

6-inch/160mm

A2-5 Electric Spindle

50-3000rpm

SC-4036DY series is designed for compound machining of small high-precision complex parts. Adopts Japanese high-low rail 30° structure, equipped with high-torque spindle and 12-station BMT-40 turret. Y-axis function enables complex multi-surface machining.

1. Bed structure: Integrated casting bed with high load capacity, wear resistance, and high rigidity mechanical properties. Provides stable base support even under heavy cutting conditions.

2. Precision spindle: A2-5 electric spindle with high torque and direct drive. Gearless spindle reduces vibration and noise. Front end uses double-row roller bearings, rear end uses matched angular contact bearings to withstand heavy loads.

3. Guides and screws: X/Z-axis 35 roller guides (P-class heavy preload), X/Z-axis 32 high-precision ball screws (C3 grade). Widened contact surfaces enhance heavy cutting capacity.

4. Power turret: Power interface complies with DIN1809 standard, BMT-type tool holder supports 12 stations free expansion. Power head max speed 5000rpm, adjacent tool change time 0.15s.

5. Full protection design: Stainless iron inner guard effectively isolates chips, dust, and coolant from entering core components like guides and screws, preventing wear and failure, extending machine life.

Power Turret with Y-axis

SC-4036DY uses high-performance 12-station BMT-40 turret with Y-axis travel ±35mm. Directly mounts various tools without additional adapter plates.

Bidirectional positioning, short tool change time, high positioning accuracy. Optional power tool holders enable turning, milling, boring, drilling, tapping. Capable of complex turning-milling compound processing.

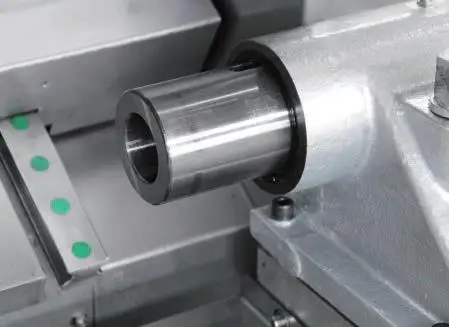

Electric Spindle

Adopts A2-5 electric spindle design with 7.5kw built-in motor.

"Zero transmission" eliminates vibration from belts, thermal expansion errors during milling, and indexing errors from buffering. Saves 30% energy compared to traditional mechanical spindles under same conditions.

Spindle through-hole diameter up to 52mm, easily processes small-medium shaft parts. Max spindle speed 3000rpm.

High-Rigidity Hydraulic Tailstock

Equipped with high-rigidity hydraulic tailstock system. Manual adjustment stroke 200mm, automatic sleeve stroke 100mm, Morse taper #5 design.

No worry about shaft workpiece wobble, ensures stable machining under heavy cutting conditions.

Ultra-rigid box-type bed structure resistant to thermal displacement.

SC-4036DY Technical Specifications

Detailed technical parameters

| Item | Specification | SC-4036DY |

|---|---|---|

| Machining Capacity | Turret Specification | T12 |

| Max Swinging Diameter mm | 400 | |

| Standard Machining Diameter mm | 160 | |

| Max Machining Diameter mm | 280 | |

| Max Machining Length mm | 230 | |

| Bar Machining Diameter mm | 35 | |

| Travel | X-axis Travel mm | 180 |

| Y-axis Travel mm | ±35 | |

| Z-axis Travel mm | 260 | |

| Spindle | Speed (min⁻¹) | 3000 |

| Min Indexing Angle (Cs control) deg | - | |

| Spindle Nose | A2-5 | |

| Through Hole Diameter mm | 52 | |

| Bearing Bore Diameter mm | 90 | |

| Turret | Turret Type | Direct Mount |

| Tool Capacity (pcs) | 12 | |

| Rectangular Tool Shank Height mm | 25 | |

| Boring Bar Shank Diameter mm | 32 | |

| Tailstock | Tailstock Travel mm | 200 |

| Tailstock Sleeve Diameter mm | 75 | |

| Tailstock Sleeve Taper | MT.5 | |

| Tailstock Sleeve Travel mm | 100 | |

| Rapid traverse speed | Rapid Traverse m/min | X:30 / Z:30 |

| Motors | Spindle Motor (30min 60%/cont) kW | 7.5 |

| Rotary Tool Motor (15min/cont) kW | - | |

| Feed Axis Motor kW | X:1.7 / Z:1.7 | |

| Hydraulic Pump Motor kW | 1.5 | |

| Coolant Pump Motor kW | 0.4 | |

| Power Requirement | Power kVA | 11 |

| Tank Capacity | Hydraulic System L | 50 |

| Lubrication Oil L | 2 | |

| Coolant L | 60 | |

| Machine Dimensions/Weight | Machine Height mm | 1950 |

| Floor to Spindle Center Height mm | 980 | |

| Footprint (Standard) mm×mm | 1950×1400 | |

| Machine Weight kg | 2800 |

Request SC-4036DY Technical Details

Contact us for custom solutions and special offers