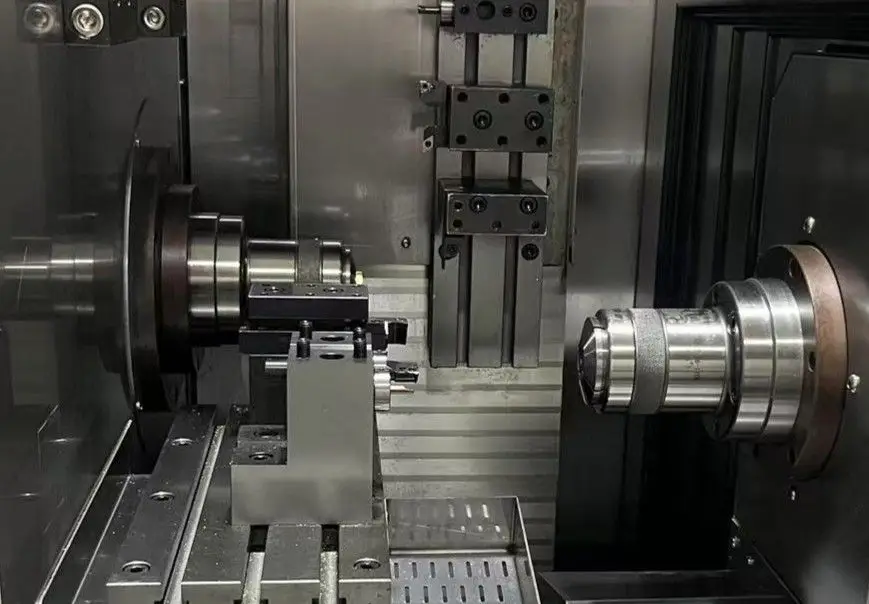

Dual Spindle CNC Turning-Milling Center for High-Efficiency Production

SC-40-40

Dual Tool Posts

Optional Live Tools

Main Motor

7.5kW × 2

Hydraulic Collet

6140 Collet

A2-5 Electric Spindle × 2

50-3000rpm

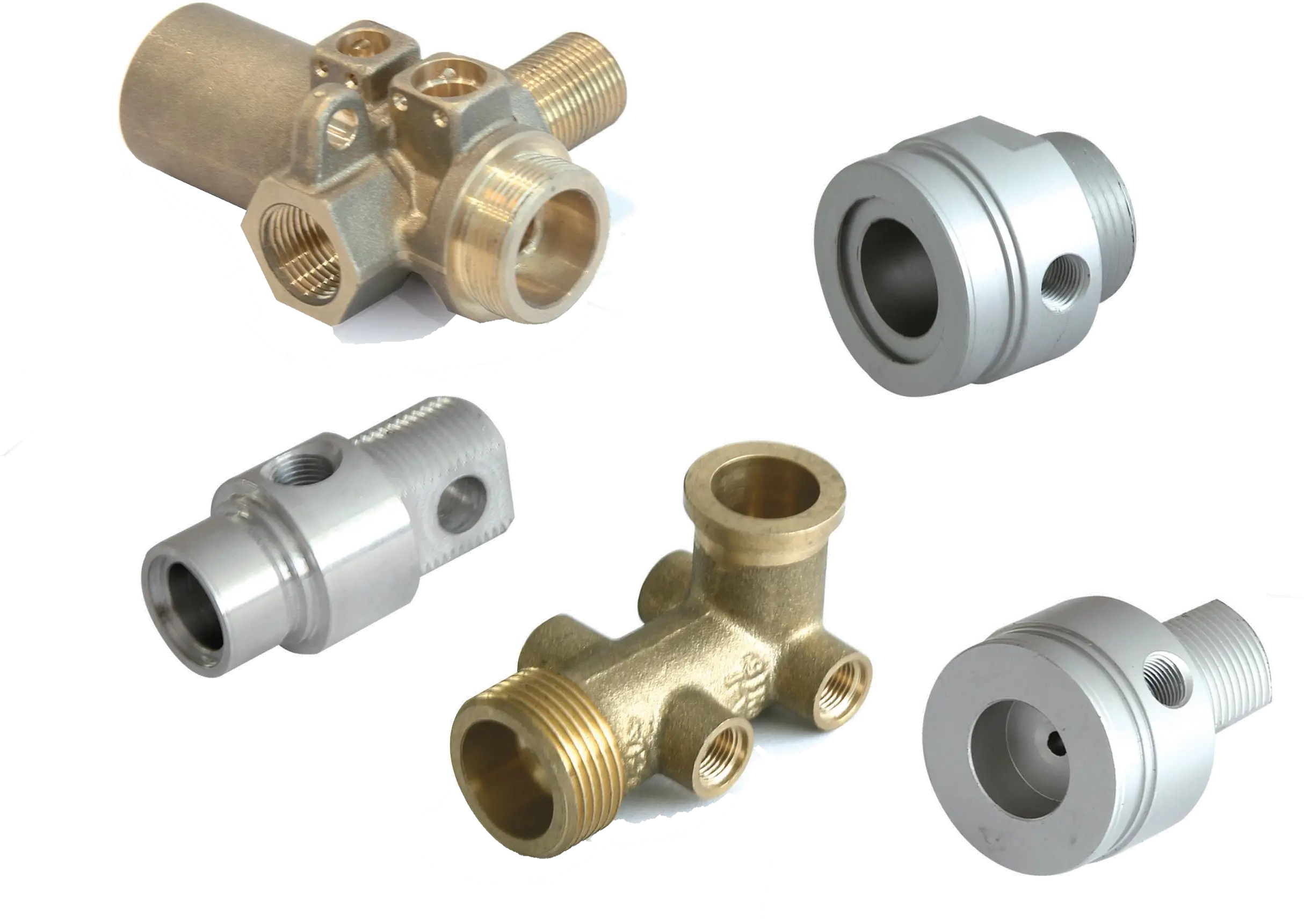

SC-40-40 series designed for batch multi-variety production, primarily for bar materials under Ø40mm. Dual spindle + optional dual live tools, flexible for shaft/symmetrical parts and turning-milling workpieces completed in one operation.

1. Integral cast bed. "One vertical, one horizontal staggered" structure improves vibration resistance, reduces footprint. Dual spindle layout supports automatic part transfer continuous machining.

2. X/Z axes equipped with Taiwan Hiwin P-class heavy preload roller guides (35 roller guides + 8 sliders) and Taiwan Yintai C3-grade ballscrews (3210 type).

3. Dual A2-5 spindles with high torque, powerful direct drive, gearless design reduces vibration and noise.

4. Taiwan Syntec 22TB system drives X/Z axis servo motors, with automatic lubrication ensuring continuous high-precision operation.

5. Automation options: Bar feeder, auto unloader for fully automated production, labor saving. One operator manages 8-12 machines.

Dual Spindle Synchronous Machining System

SC-40-40 features two independent A2-5 electric spindles (7.5kW each) with dual-channel function. Enables workpiece transfer between main/sub spindles for simultaneous machining, reducing secondary clamping time, greatly improving production efficiency.

Live tools can be installed on both sides based on customer requirements, enabling turning-milling compound functions.

High Precision Rigid Structure

High-strength cast iron bed ensures long-term stable operation. Imported C3-grade ballscrews and linear guides provide high rigidity and precision motion control. Japan NSK-P4 grade angular contact bearings ensure spindle stability.

X/Z axes use P-class heavy preload roller guides (35 roller + 8 sliders), strong vibration resistance for heavy cutting.

X/Z axes repeat positioning accuracy 0.005mm, absolute positioning accuracy 0.005mm.

Modular Expansion Capability

Optional live tools on both ends support turning-milling compound machining (drilling, milling slots, tapping).

Taiwan Syntec 22TB CNC system with Syntec original X/Z axis servo motors for fast response.

Optimized tool magazine design reduces tool change time, improving machine utilization.

SC-40-40 Technical Specifications

Detailed technical parameters

| Item | Specification | SC-40-40 |

|---|---|---|

| Machining Capacity | Swing Diameter (mm) | 400 |

| Max Cutting Diameter (mm) | 36/42 | |

| Max Machining Length (mm) | 100 | |

| Standard Machining Diameter (mm) | 35/42 | |

| Travel | X-axis Travel (mm) | 350 |

| Z-axis Travel (mm) | 220 | |

| Spindle | Spindle Type | A2-5 |

| Draw Tube Bore (mm) | 36/42 | |

| Spindle Bore (mm) | 48 | |

| Spindle Speed (r/min) | 50-4000 | |

| Rapid Traverse | X-axis Rapid Traverse (m/min) | 15-20 |

| Z-axis Rapid Traverse (m/min) | 15-20 | |

| Accuracy | X/Z Repeat Positioning Accuracy (mm) | 0.005 |

| Spindle Indexing Repeat Accuracy | ≤20 arcsec (0.006°) | |

| Spindle Indexing Absolute Accuracy | 70 arcsec (0.02°) | |

| X/Z Absolute Positioning Accuracy (mm) | 0.005 | |

| Motor Power | Spindle (C-axis) Power (kW) | 4/5.5/7.5 |

| Dimensions/Weight | Tool Size (mm) | 20/25 Tool Holder |

| Machine Weight (kg) | 3500 | |

| Machine Dimensions L/W/H (mm) | 2150/1600/1750 |

Ready to upgrade your production line?

Contact us now for customized solutions and quotes